Highly impressive quality – 100% made in Austria

Company history

12 / 2015

Modernization and expansion of the production plant

In addition to the rebuilt assembly hall, a new 14-metre high varnishing area as well as three raw material storage halls were built. In total the production area has more than doubled. The production area including warehouse got expanded by almost 5,500m². At the end of the year, only 6000 pairs of poles less were produced less than the year before, supplies kept well.

4 / 2015

Re- and new construction

In March, Mag. Thomas Roiser presented the first building plans to the authorities. The negotiation was shortly after Easter, construction started in May. The goal was clear, we did not only rebuild the plant but also modernized it at the same time. Therefore we built five halls and invested 7,5 million Euros.

2 / 2015

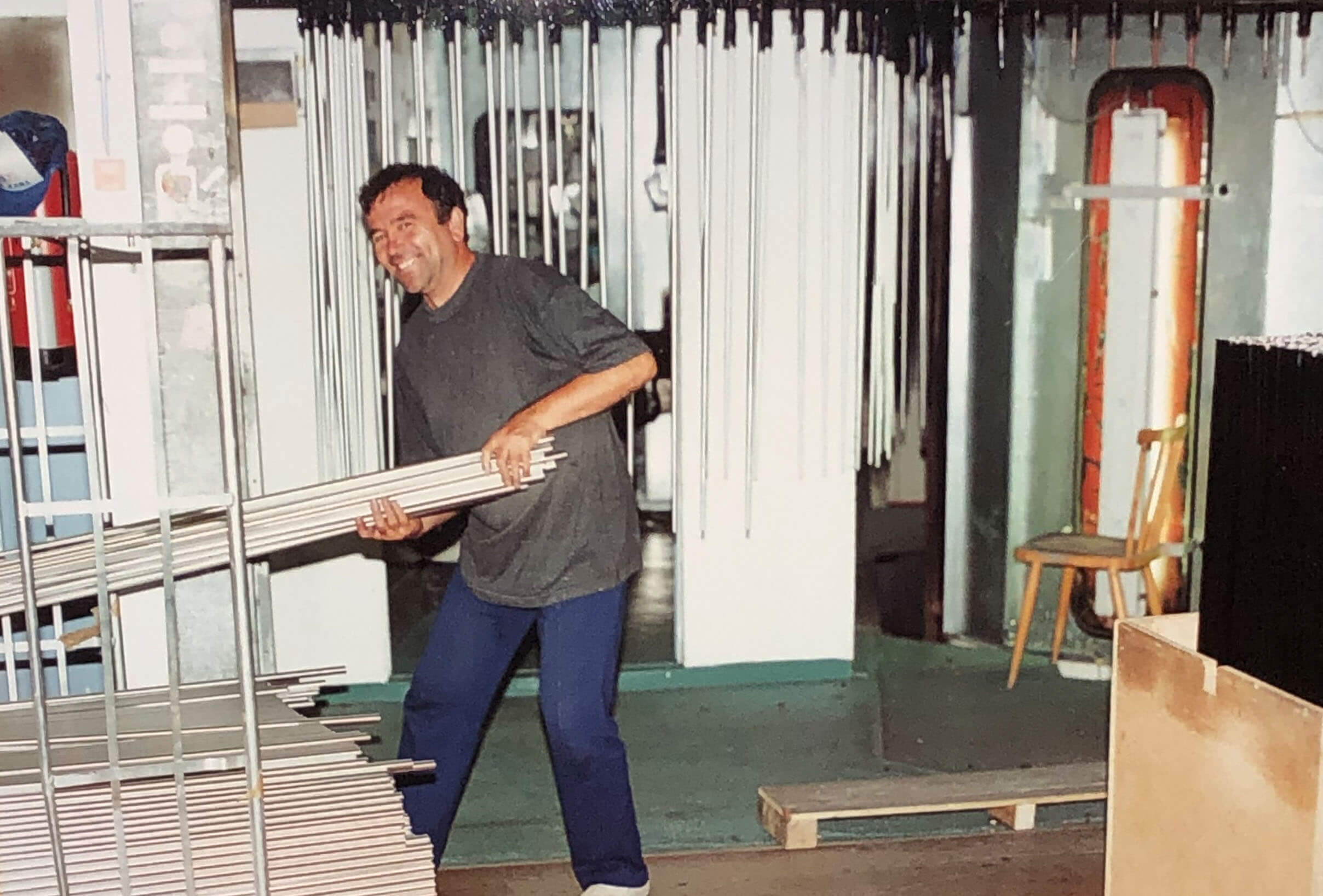

Major fire in the production facility

A major fire shut down the production plant for a moment. The shift was about to start, the first workers were already on site, when the fire was spotted at exactly 05.54.05. a.m. Only one day after returning from the largest sporting goods fair – the ISPO in Munich - the fire destroyed a part of the pole production site. A two-storey hall burnt out completely. A second one was destroyed to 40%. The fire was caused by a technical defect and amounted to a damage of several million euros. However, a large part of the production was able to continue. It quickly became clear that the plant will be rebuilt. Due to the production volume we had to outsource the varnishing work to five companies and deliver the poles up to the Aosta valley. Additionally, several halls in the region had to be rented for storage. After ten days we started with our production again.

2008

Construction of a new logistic centre

During the financial crisis in 2008, the demand for our products increased and required a new logistics centre at lake Mondsee. With the construction of an additional logistic centre in Burgau/Mondsee our floor area tripled. At the same time we created apartments for employees to offer them affordable living if they are from further away.

2007

New establishment in the USA

We were pleased to achieve great sales success with our products overseas and established an own branch office in Kent/Washington USA due to logistical reasons. The offices were set up and beside the existing sales staff three new employees got hired to react even faster to customer requests and deliveries.

2006

Expansion of the administrative wing

KOMPERDELL is growing steadily and represented its products all over the world. Therefore the administrative wing for marketing, sales, procurement, trade fair and event management got expanded. In addition to production, our company headquarters at lake Mondsee also houses development, design, marketing, sales and procurement. This enables us to manufacture individually and quickly and offer an unbeatable service for our retail and industry customers.

2005

New sales market: USA and Canada

Thomas Roiser’s hard work payed off, North America was the largest market in 2005 and hence the first sales staff for KOMPERDELL USA were employed.

2004

Enlargement of the production site by 5,000m²

A new building was planned to enlarge the production site by 5,000m². The doubling and complete rebuilding of the KOMPERDELL facility was covered by an investment of 25 million Schilling. The result was a completely new production site with the most modern machinery park which was a big step forward towards an even faster production. For the first time in history Komperdell produced almost 1 million pairs of poles (997,000).

2000

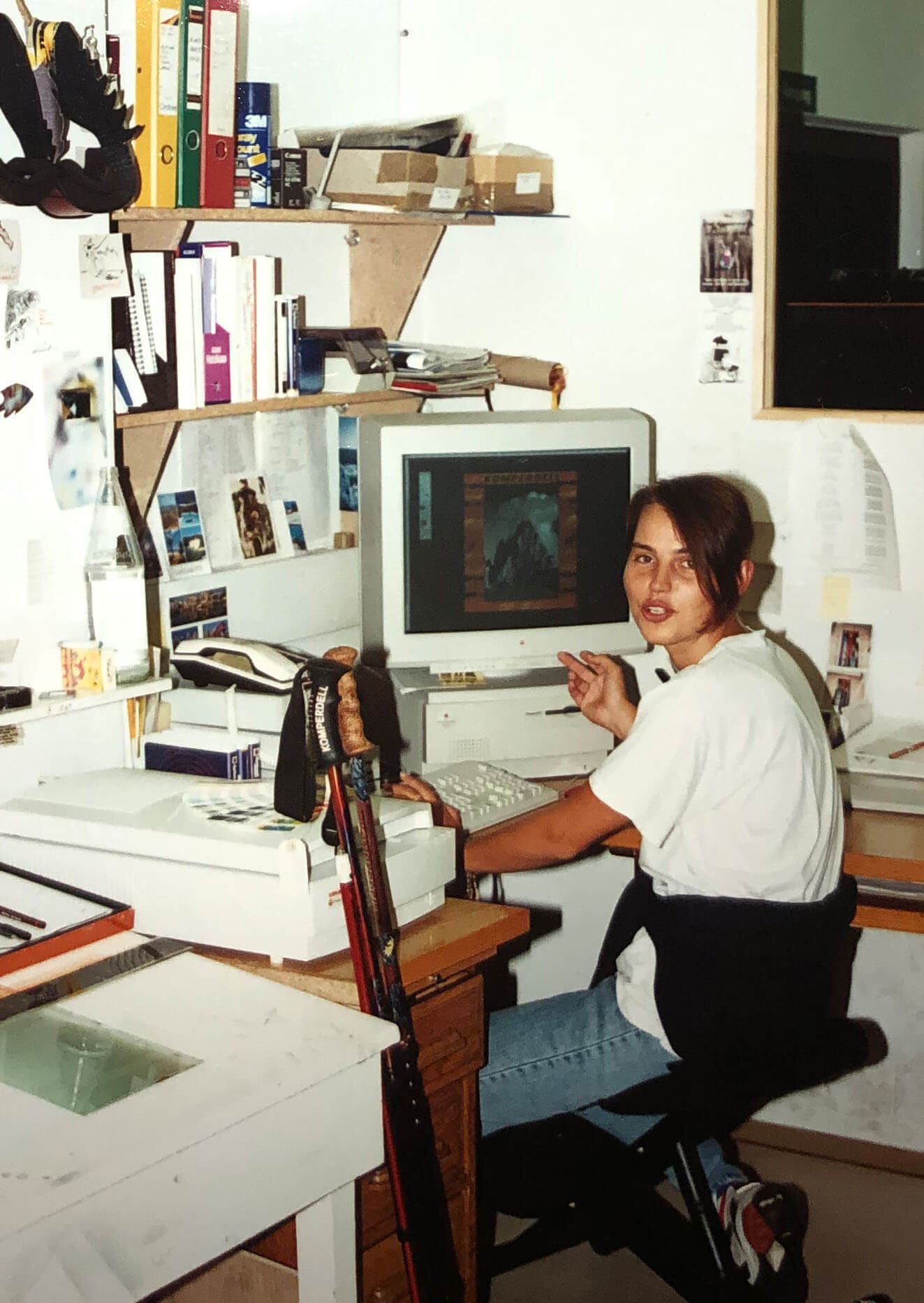

Entry into modern age

At this time, KOMPERDELL produced 80% for other brands, only 20% of the poles were sold in the name of Komperdell. Since branding became way more important, the first computers for the marketing department got purchased. From now on, the focus was on an own KOMPERDELL brand collection as well as a growing technological future with permanent innovations. However, the industrial business has never declined because we put a lot of service, heart and soul into our customers products. Ever since we do not just want to satisfy our customers, we want to excite them again and again!

1999

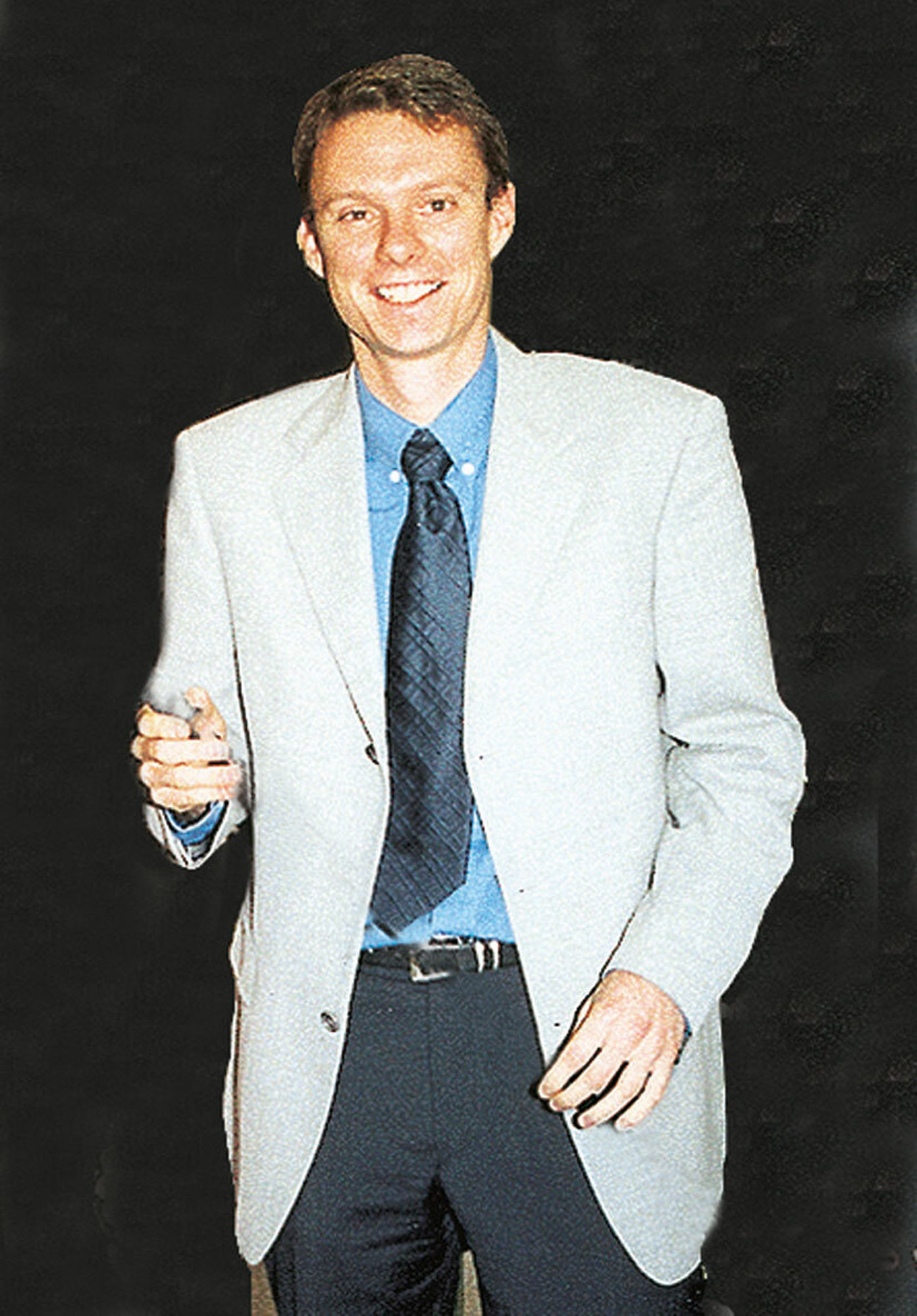

Complete management handover to Thomas Roiser

Erich Roiser handed over the whole management of CAMARO and KOMPERDELL to Thomas Roiser. Similarities remain, even if certain themes differ. From now on, Erich Roiser dedicates himself more to Komperdell Golf and his son successfully leads the company together with a young, sports-loving team into a new future and, above all, expanded business relations overseas.

1997

Change of generations

Thomas Roiser brought a breath of fresh air into the company when he joined his father in managing the companies CAMARO and KOMPERDELL in 1997. Growing up in a sports-loving family, where many things revolved around business, he got to know the habits of the sports industry at a young age.

1991/1992

Expansion in Mondsee

Due to a constantly increasing production volume, the space became too tight and hence the warehouse and shipping department was expanded many times over. An important step towards an even more conscious approach to environment was switching to water-soluble varnishes! We stand for a conscious and sustainable approach to the environment, which is why our production works with non-toxic and partly recycled materials, as well as the most environmentally friendly production processes with most modern varnishes and production facilities.

1989

Foundation of KOMPERDELL GOLF

KOMPERDELL Golf was founded out of joy and personal interest by Erich Roiser in order to balance the business. The pole factory was a great advantage as KOMPERDELL processed approx. 500,000 graphite tubes of various qualities for alpine and hiking poles. This know-how was essential for the production of golf clubs. Erich Roiser’s enthusiasm for golf was stirring – even today it is still a concern for us to develop and improve our golf products together.

At the same time, we started manufacturing ski poles for almost all leading ski brands of that time such as Head, Fischer, Kästle, Hartskis...

1987

Thomas Roiser follows into the footsteps of Erich Roiser

The youngest son of Erich Roiser, Thomas Roiser, started working in the company. On his first trip with a 130kg luggage to the American trade fair SIA, he immediately took up the opportunity to build up the market overseas.

1986

New establishment in Germany

Our German branch office in Freilassing to service the EU market was founded. More and more of our products were exported abroad. The export quota at that time was already 80%. Thanks to good contacts, we relatively quickly became international and the branch enabled us to deal with other countries even faster.

1984

The company buildings grow

The company headquarters were growing over the years in proportion to the number of employees, which in the late 1980s amounted to 50 people. Today, KOMPERDELL employs around 200 people and produces over 1,000,000 pairs of poles per year.

1983

The family Roiser (CAMARO) took over KOMPERDELL

Mr. Erich Roiser took over the company KOMPERDELL since the family Bednar had financial difficulties. Until 1983 only active in water sports, the successful company CAMARO was looking for a counterpart to the summer-focused business to establish a second mainstay. Thus, the production of KOMPERDELL got relocated to St. Lorenz near Mondsee in the beautiful Salzkammergut. The traditional family businesses were brought together at this location and can still be found there today. KOMPERDELL was completely modernized and repositioned. An investment of 20 million Schillings in the machinery park created the world’s most modern pole production at that time. KOMPERDELL developed into a technology leader in the sector of skiing and telescopic poles on the international market. Of course, environmental protection already played an important role at that time. Great emphasis was placed on integrating the factory buildings with a production area of 5000m² harmoniously into the landscape.

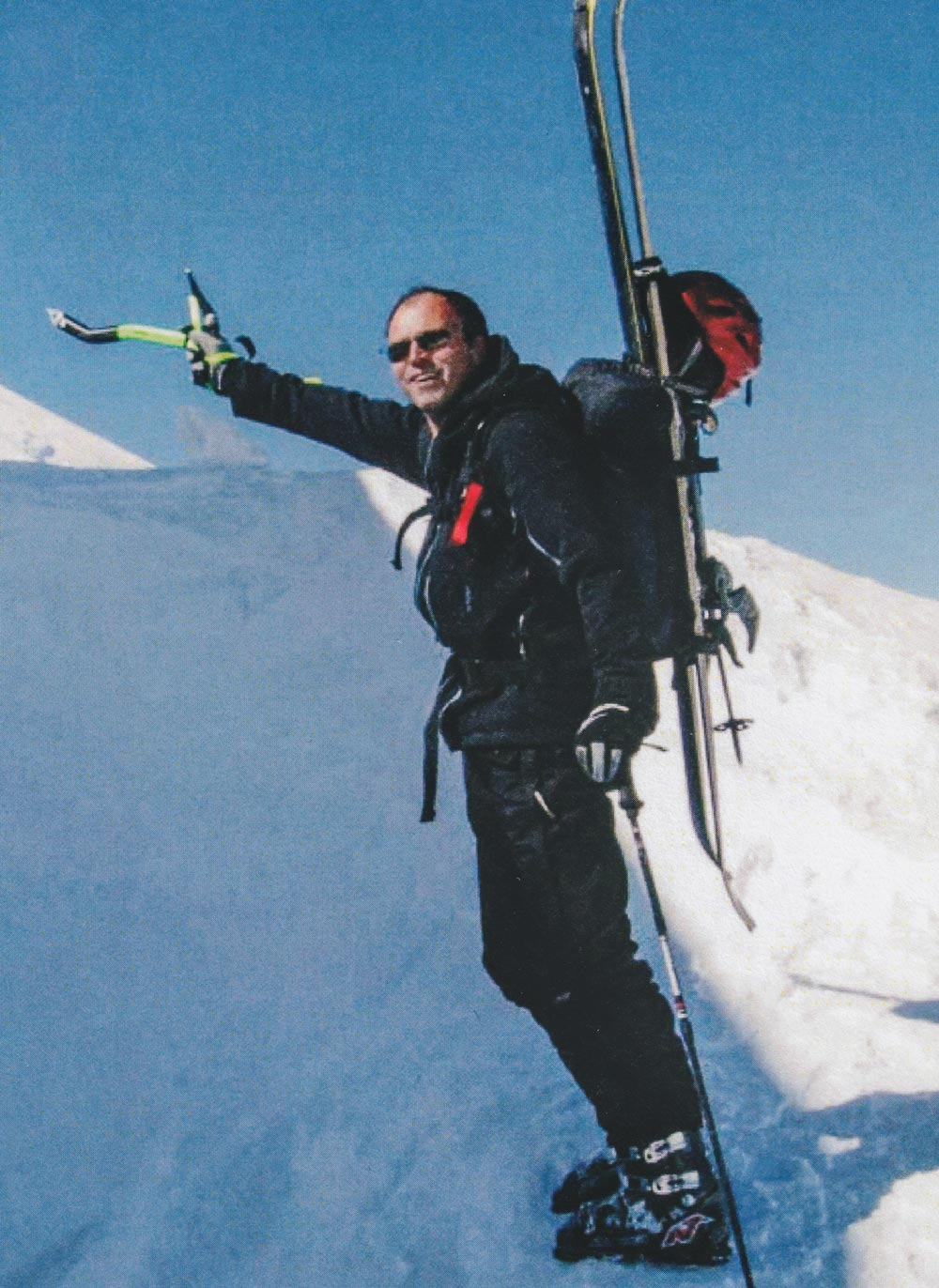

1980 - 2009

Christian Hager

In 1980, as an intern at the time, one of the employees who would become the face of the Camaro and Komperdell brands on the German market for decades applied.

Privately a passionate surfer, skier and climber, professionally Christian was above all a true sales talent.

The dynamics of sales, the joy of working with customers and his ability to constantly identify and seize new opportunities shaped his work.

Christian had an extraordinary gift for always recognizing new chances and possibilities in a sales talk and so it was not unusual that at the end of a Komperdell appointment, both a Komperdell order and a much larger Camaro order came out.

Tragically, Christian died in an avalanche accident in 2011. However, it is nice to see that even today, more than 10 years after his death, he still appears in customer discussions.

Even today, more than 10 years after his death, he is still a part of Camaro and Komperdell for many of our customers. Even today his name often comes up in conversations with our customers. It is nice to see the respect and recognition he has gained from his customers, in our house and in our family.

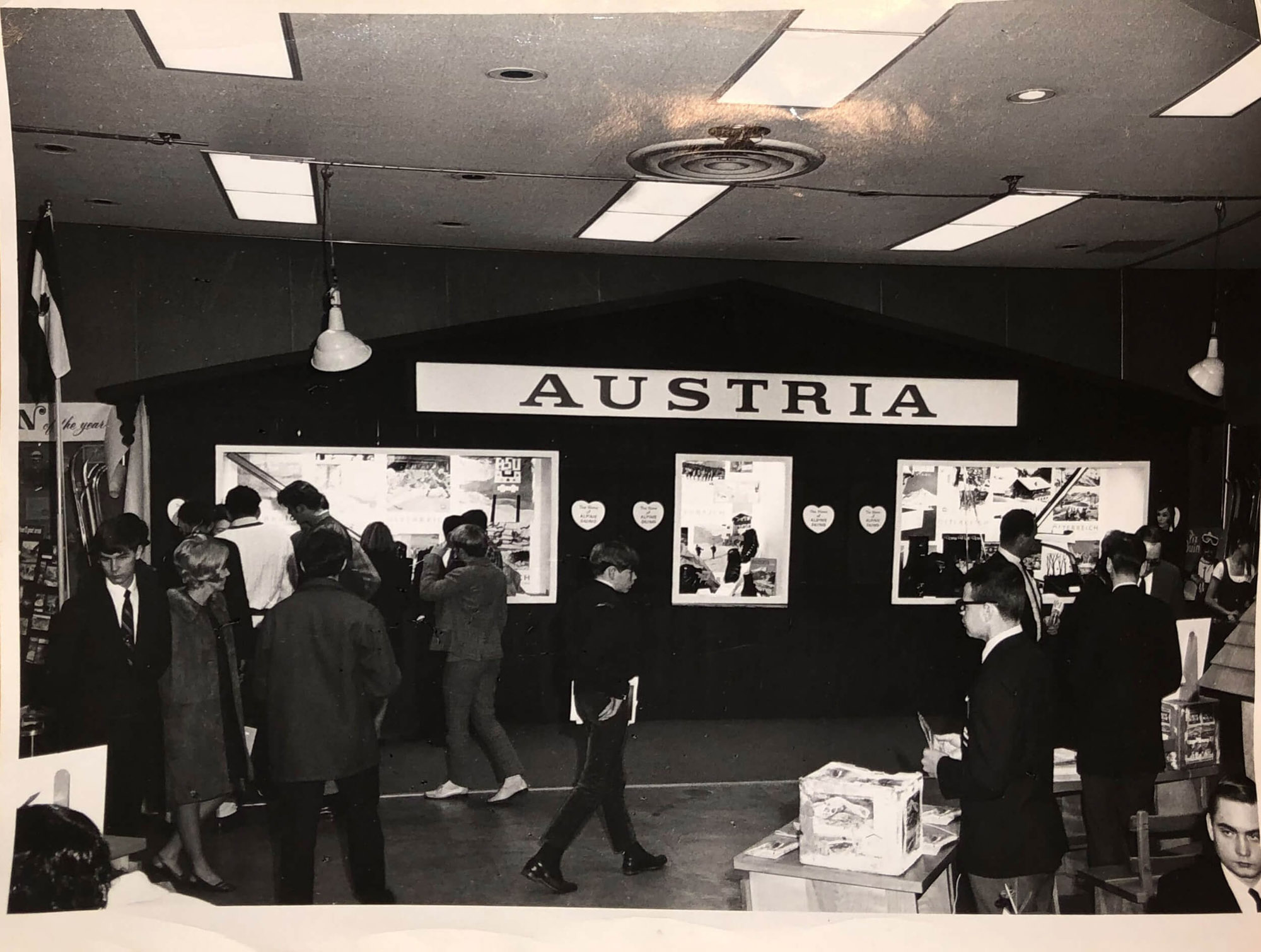

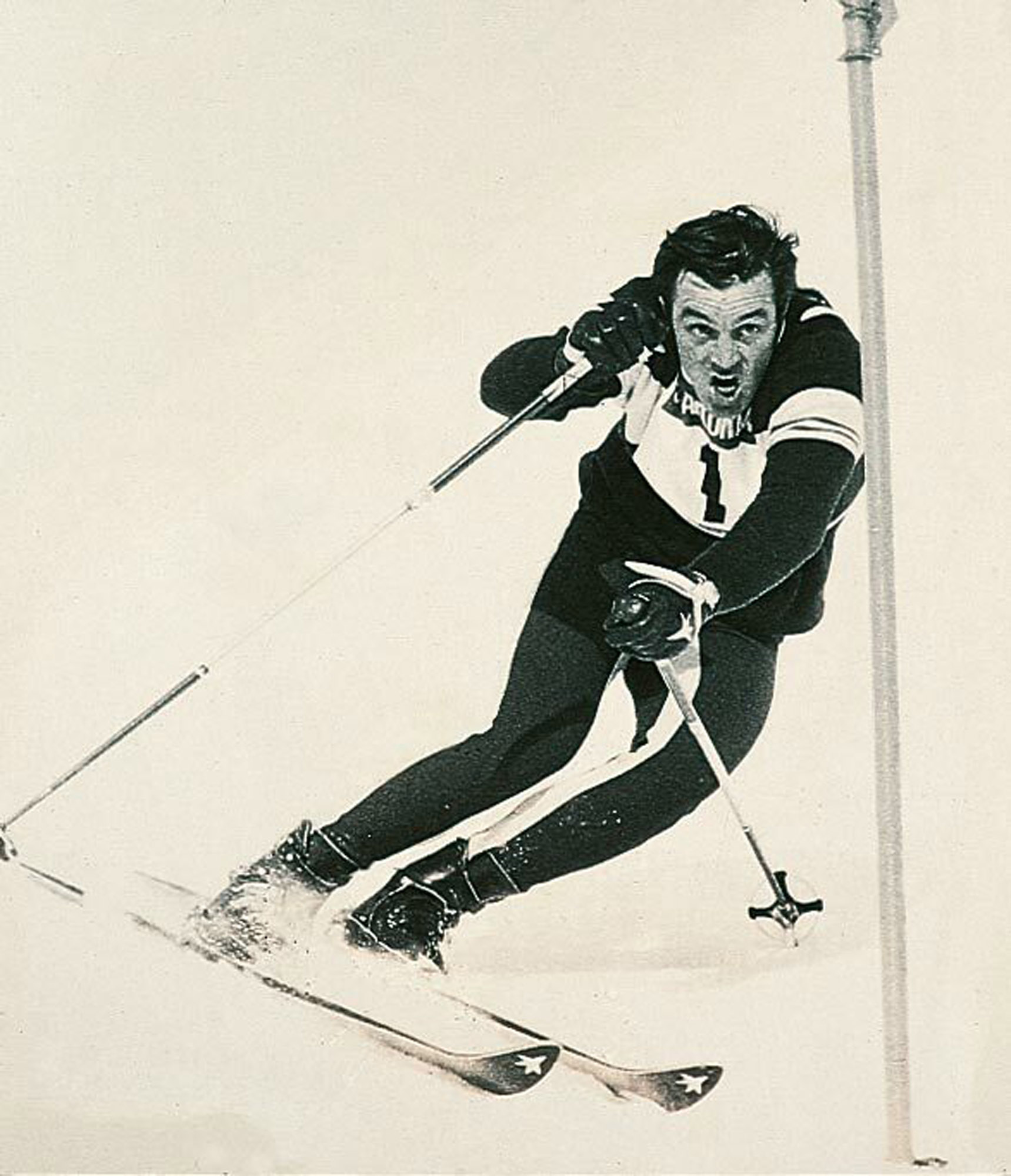

1976

Olympic winter games

The Austrian success story continues: Franz Klammer wins gold in downhill at the Olympic winter games in Innsbruck - of course with KOMPERDELL poles. With 25 downhill victories Franz Klammer is the most successful downhill racer in the world cup history, ahead of Peter Müller with 19 victories. He won all classic downhill races, even the Hahnenkamm race in Kitzbühel four times, the Lauberhorn race in Wengen three times and four times at at Saslong in Gröden. 1975 he even set a record with a lead of 3.6 seconds in Wengen. KOMPERDELL also became exclusive material supplier of the Austrian ski pool, as well of many other leading international skiing nations. We established ourselves as the most successful brand in racing!

1970

More than 150.000 pairs of skiing poles

Production output increased steadily and in 1970 KOMPERDELL produced more than 150.000 pair of skiing poles per year for the first time in history. As aluminium gained more and more importance, steel and wooden poles got replaced by this much lighter material.

1956

the black flash from Kitzbühel

Toni Sailer, the black flash from Kitzbühel, won at the Olympic games in Cortina. With the new KOMPERDELL steel poles, he achieved gold in the disciplines downhill, giant slalom and slalom. The longstanding amicable connection to KOMPERDELL remained throughout his life, even as an enthusiastic golfer.

1922

Firmengründung Komperdell

1922 wird die Firma KOMPERDELL von der Familie Bednar in Wien gegründet, wo man zunächst Wander-, Spazier- und Billardstöcke aus Haselnussholz fertigte. Zu dieser Zeit sind Wander- bzw. Skistöcke noch ein Unikum. Doch das soll sich rasch ändern. Aus der kleinen Drechslerei in Wien entwickelte sich ein Unternehmen, das 1928 bereits 50 Mitarbeiter beschäftigte und schon bald zu den führenden Herstellern von Skistöcken zählte und im Rennlauf schnell die ersten Erfolge feiert.